The action: Use a structured conversation, such as the A3-problem solving method, or Toyota Kata-questions, to increase your team’s ability to improve.

We come to work, not just to do our jobs, but to also learn how to do our work better.

Steven Spear, The High-Velocity Edge

The long form:

You are committed to becoming a learning organisation. To create a rhythm of improvement your day starts with a daily pulse meeting, and the week ends with a weekly improvement meeting (see f40: Make progress with weekly improvement meetings). You have assigned a few problems for next week’s improvement meeting, but come next week and no-one has made any progress. What happened?

Well, creating a culture of continuous improvement is very much like exercising. You have to start gradually, be prepared for slow progress in the beginning, but keep at it and you will see results.

So even though you yourself are learning to learn, you also need to act as personal trainer to your team. I’ve found two approaches to be helpful (and possible to combine):

A3-method

Putting ideas on paper forces you to clarify your thinking, and makes it easier to communicate. The A3-method uses a sheet of exactly that size and encourages you to first really understand the problem, and then test counter-methods.

In it’s simplest form you can just divide the sheet in half. On the left-hand side you write what you know about the problem. On the right-hand side you make a record of your experiments and your proposed solution.

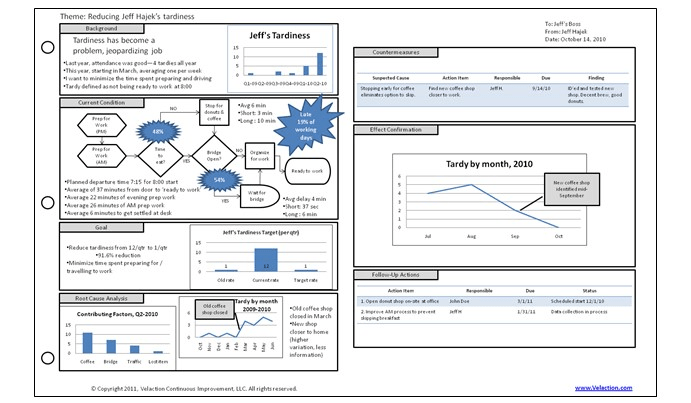

If necessary, you can always use more complex templates, such as this one from Velaction.

It takes two to A3

John Shook, Managing to Learn

The A3-report really shines when used as a coaching tool and not a bureaucratic formality. Say you have a problem of missing bandages in the exam rooms. In the improvement meeting on Friday, Amanda volunteers for the task. This meeting is only for assigning projects, so the real work gets done during the week. Every day in the following week Amanda brings an A3-sized paper on which she writes what she has learned about the problem, what the underlying causes are and who has a stake in it’s solution. On Wednesday she tries the first experiment and updates the A3 accordingly.

Toyota Kata

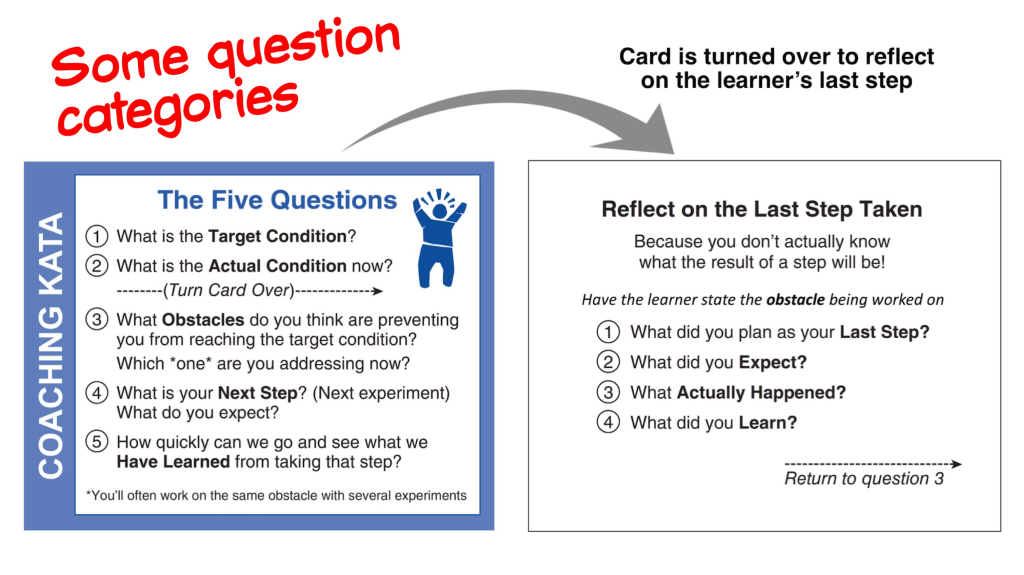

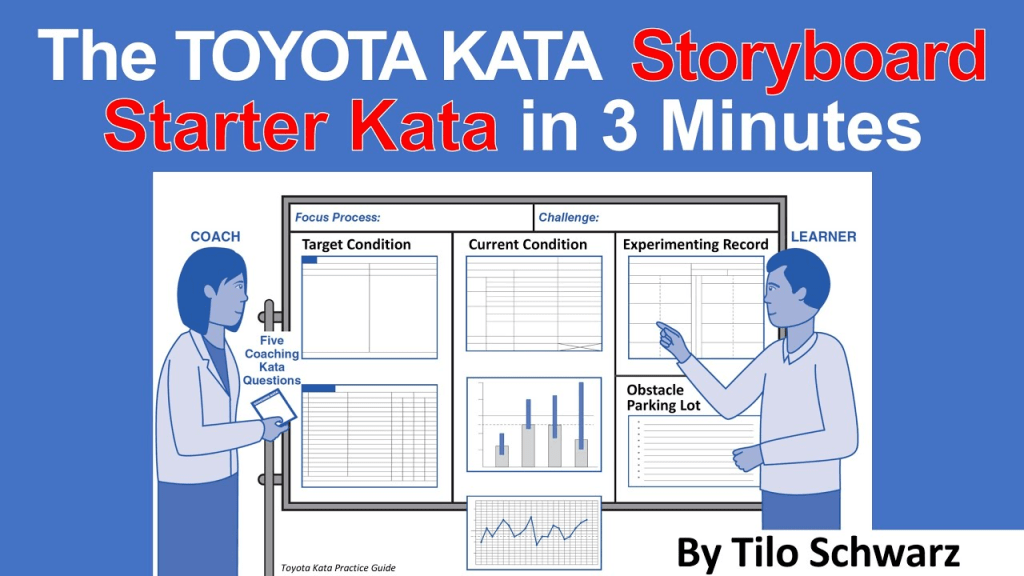

A Kata is a pattern, a repeatable but simplified set of steps, like playing scales on an instrument. In his book on the Toyota Kata, Mike Rother asks if we missed the real secret of Toyota’s success – training people to be problem-solvers, and managers to be problem-solving coaches. And the best way to learn is to practice with a structure – such as his coaching-kata questions.

Ideally you have 10-minute coaching meeting every day with the team-member who is working on a problem. An example conversation could be:

You: 1. What is the target condition?

Amanda: It would be great to completely avoid stock-outs of bandages in the exam rooms.

You: 2. What is the actual condition now?

Amanda: On average we run out 2-3 times a week, so the vet has to leave the patient and go look for more bandages.

(If you have started experimenting already you turn the card over and discuss what the last step was and what you learned from it).

You: 3. What obstacles do you think are preventing you from reaching the target condition?

Amanda: There are several, but the one we will work on first is that no-one feels it is their responsibility to refill the drawers.

You: 4. What is your next step?

Amanda: Together with the evening-shift nurse we have created a standard procedure for refilling the drawers every evening at 19:00. We expect this to work, but that we may have to create a short training program for the new interns.

You. 5. How quickly can we go and see what we have learned from taking that step?

Amanda: Let’s ask the evening nurse how it went later tonight.

Combining the two

Usually with the Kata method you use a board. But for smaller problems you could easily use the questions with an A3-sheet instead, combining the two methods. Try it and see what works for you!